How to Choose the Right Drill Bit for Any Job!

When it comes to DIY projects, home improvement tasks, or professional work, drilling is often at the core of the process. Whether you are putting up shelves, installing a light fixture, or building furniture, a reliable drill and the correct drill bit are essential for a successful outcome. However, choosing the right drill bit for each job is crucial to ensuring that your work is efficient, precise, and safe.

With so many types of drill bits available, it can be overwhelming to decide which one is best suited for the job. We’ll cover everything you need to know about choosing the right drill bit, from understanding the various types to selecting the proper size and material. By the end of this post, you’ll be equipped to tackle any drilling project with confidence!

Why Does Choosing the Right Drill Bit Matter?

Before diving into the types of drill bits, let’s talk about why it’s so important to choose the right one for the job. The wrong drill bit can:

- Damage the material: If you use a drill bit that isn’t designed for the material you’re working with, you risk damaging the surface, whether it’s wood, metal, masonry, or plastic.

- Cause inefficient work: The wrong bit may not drill effectively, leading to longer work times and frustrating results.

- Increase the likelihood of injury: Improper drill bits can slip, break, or overheat, which can lead to accidents.

- Hurt your drill: Using the wrong drill bit can lead to excessive wear on your tool, reducing its lifespan and potentially causing it to malfunction.

Understanding the right drill bit for your specific job is key to maximizing both your tools and your project’s success.

Types of Drill Bits and Their Uses

1. Twist Drill Bits

Description: Twist drill bits are the most common and versatile type of drill bit. They have a cylindrical shape with two cutting edges that spiral down the length of the bit. Twist bits are available in a variety of sizes, materials, and coatings, making them adaptable to different materials.

Best for:

- Wood

- Metal

- Plastic

- Soft concrete

Why Use Them: Twist drill bits are the go-to option for most basic drilling tasks. They are widely available, easy to use, and perfect for general-purpose drilling in a variety of materials.

2. Brad Point Drill Bits

Description: Brad point drill bits are specially designed for wood and other soft materials. They have a sharp point at the tip that ensures precise entry into the material, which reduces the chance of wandering and makes clean holes.

Best for:

- Wood (especially hardwoods and plywood)

- Softwood

Why Use Them: The brad point tip ensures accuracy and minimizes splintering, making it the ideal choice for drilling into wood. If you’re working with a wooden project where precision is key, brad point bits are a must.

3. Masonry Drill Bits

Description: Masonry drill bits are designed with a carbide or diamond tip that can handle hard, brittle materials like concrete, brick, stone, and mortar. These bits are typically thicker and have a more robust design to handle the tough nature of masonry.

Best for:

- Concrete

- Brick

- Stone

- Mortar

Why Use Them: If you’re drilling into any material that’s more solid than wood or metal, a masonry drill bit is essential. These bits have a unique design that helps break through tough materials efficiently.

4. Spade Drill Bits

Description: Spade drill bits have a flat, paddle-like shape with a sharp point at the tip. They are ideal for drilling large holes in softwood or other relatively soft materials.

Best for:

- Wood

- Soft plastics

Why Use Them: Spade bits are great for drilling larger holes quickly and are an affordable option for basic projects. If you’re creating larger openings, like for pipe installations or wiring, a spade bit will work well.

5. Auger Drill Bits

Description: Auger bits are typically used for drilling deep, large holes in wood. They have a screw-like design that pulls the bit through the material, which helps create smooth and precise holes. Auger bits often feature a lead screw tip, which helps guide the bit into the wood.

Best for:

- Wood (especially for deep holes)

Why Use Them: Auger bits are ideal for when you need to drill deep holes in wood. The lead screw tip ensures that the bit doesn’t wander, and the smooth design results in cleaner, more consistent holes.

6. Forstner Drill Bits

Description: Forstner bits are designed for drilling flat-bottomed holes in wood. They have a unique rim around the edges that allows them to create clean, precise holes without splintering the material.

Best for:

- Wood

- Plywood

- Softwoods

Why Use Them: Forstner bits are best used when you need to drill clean, flat-bottomed holes. They are often used for tasks like drilling holes for dowels, hinges, and hardware, where precision and clean edges are essential.

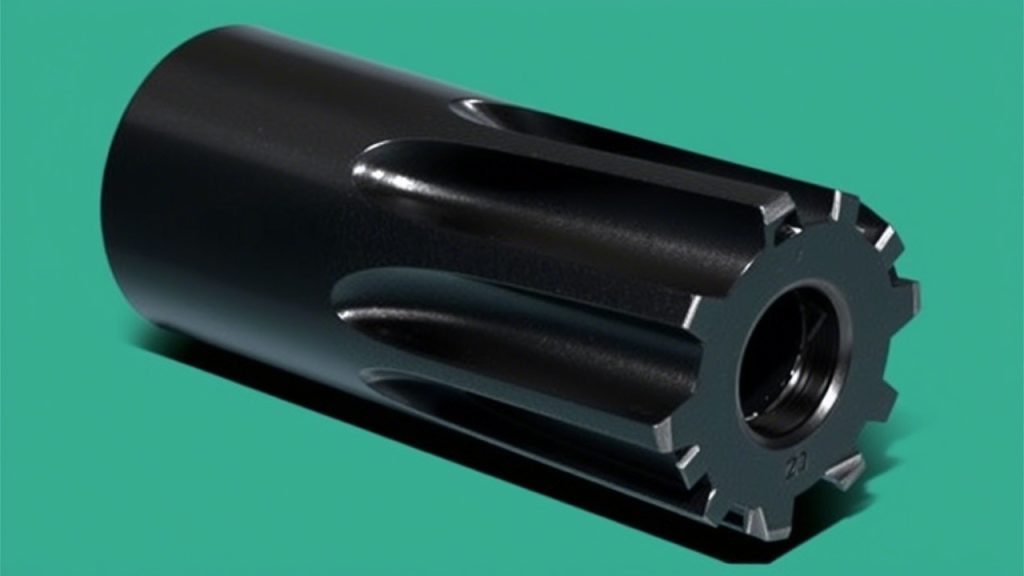

7. Hole Saw Drill Bits

Description: Hole saws are large, cylindrical bits that are designed to cut big, round holes in materials. They feature a sharp edge that makes them ideal for cutting through wood, metal, plastic, and drywall.

Best for:

- Wood

- Drywall

- Plastic

- Metal (with specific hole saws)

Why Use Them: Hole saw bits are perfect for larger diameter holes, such as for pipes, door hardware, or electrical outlets. Their design allows you to create larger openings without needing to use a specialized router or jigsaw.

8. Cobalt Drill Bits

Description: Cobalt drill bits are made of a high-speed steel alloy with a high percentage of cobalt added to the mix. This makes them much more heat-resistant and durable compared to standard steel drill bits.

Best for:

- Hard metals like stainless steel

- Other tough materials

Why Use Them: If you’re working with tough metals like stainless steel, cobalt drill bits will stay sharper longer and perform better under heat and pressure. They are ideal for heavy-duty projects where standard drill bits might wear down too quickly.

9. Step Drill Bits

Description: Step drill bits have a unique design with a series of progressively larger steps, allowing you to drill different sizes of holes with a single bit. This feature makes them ideal for drilling through thin materials.

Best for:

- Metal

- Plastic

- Sheet metal

- Thin wood

Why Use Them: Step drill bits are incredibly versatile and allow you to drill a wide range of hole sizes without switching out bits. They are perfect for drilling into thin materials like sheet metal, plastic, or even drywall.

10. Diamond Drill Bits

Description: Diamond drill bits are designed for use with extremely hard materials. They have a diamond-coated tip that allows them to drill through tough materials like glass, ceramic, and stone without cracking or breaking.

Best for:

- Glass

- Ceramic

- Stone

- Tile

Why Use Them: If you’re working with glass, tile, or any other fragile material, a diamond drill bit is the right choice. The diamond coating ensures that the drill bit stays sharp and effective, while minimizing the risk of damage to the material.

How to Choose the Right Drill Bit for Your Project

Now that you’re familiar with the different types of drill bits, it’s time to learn how to choose the right one for your project. Here are a few key factors to consider when selecting a drill bit:

1. Material Type

The material you’re drilling into plays a huge role in determining the right drill bit. Each drill bit is designed to handle specific materials, so always match the bit to the material you’re working with. For example:

- Use twist drill bits for wood, metal, and plastic.

- Use masonry bits for concrete, brick, or stone.

- Use diamond bits for glass, tile, and ceramics.

2. Hole Size

Different bits are designed to create different-sized holes. If you need a larger hole, use a hole saw or spade drill bit. For precise, smaller holes, a twist bit or Brad point will do the job. If you need to make holes of various sizes, consider a step drill bit.

3. Drilling Depth

Some projects require deep holes, while others only require shallow ones. For deep holes in wood, an auger bit is ideal, as it can drill deep, clean holes. If you only need to drill shallow holes, a standard twist drill bit or Brad point bit will suffice.

4. Drill Speed and Power

Some drill bits are designed to be used with specific speeds or power levels. For example, masonry drill bits require a slower speed to prevent overheating. Cobalt or HSS drill bits for metal, on the other hand, may require faster speeds, but they also need to be lubricated to prevent overheating.

5. Precision and Cleanliness

For more delicate or precise drilling, such as when you’re drilling for hardware or installing fixtures, choose a Brad point drill bit or Forstner bit. These types of bits provide clean, smooth holes with minimal splintering or rough edges.

10 FAQs About Drill Bits

1. What’s the difference between a twist bit and a brad point bit?

- A twist bit is designed for general-purpose use on wood, metal, and plastic. A brad point bit has a pointed tip that ensures precise entry and reduces wandering, making it ideal for wood and soft materials.

2. Can I use the same drill bit for metal and wood?

- While twist drill bits can be used for both metal and wood, it’s better to use specific drill bits for each material. Cobalt bits are best for metal, while Brad point or Forstner bits are designed for wood.

3. How do I know if my drill bit is sharp?

- A sharp drill bit will cut through material smoothly without much resistance. If your bit is struggling to drill or creating rough edges, it may be dull and need sharpening or replacing.

4. Do I need a hammer drill for masonry work?

- If you’re drilling into hard masonry like concrete, a hammer drill is a great choice as it combines the rotation of the drill bit with a hammering motion. For light masonry work, you may be able to use a regular drill with a masonry bit.

5. What material is the best for long-lasting drill bits?

- Cobalt and carbide bits are some of the most durable materials for drill bits. They are highly resistant to heat and wear, making them ideal for tough jobs like drilling through hard metals.

6. How do I prevent drill bits from overheating?

- Use cutting fluid for metal drilling to reduce heat buildup. Also, avoid applying excessive pressure, and if necessary, let the bit cool down between drilling.

7. Can I use a step drill bit on wood?

- While step drill bits are primarily used for metal and plastic, they can be used on wood for larger holes. However, spade bits or Forstner bits are usually better suited for wood.

8. Can I sharpen my drill bits?

- Yes, drill bits can be sharpened using a sharpening stone or a dedicated drill bit sharpening tool. Sharpening should be done carefully to preserve the angle of the cutting edges.

9. Why do my holes have jagged edges?

- Jagged edges often result from using a dull or incorrect drill bit. Brad point and Forstner bits are designed to minimize this issue when drilling into wood.

10. How do I know which size drill bit to use?

- Choose a drill bit that matches the size of the screw or anchor you are using. Most packaging will provide size recommendations for optimal fit.

Conclusion

Choosing the right drill bit for any job requires an understanding of the material you are working with, the type of hole you need to create, and the size and depth of the hole. With so many drill bit options available, the key is to match the right tool to the right task. By following the guidance provided in this article, you can ensure that your drilling projects are completed with precision, efficiency, and safety, ultimately transforming your DIY game.